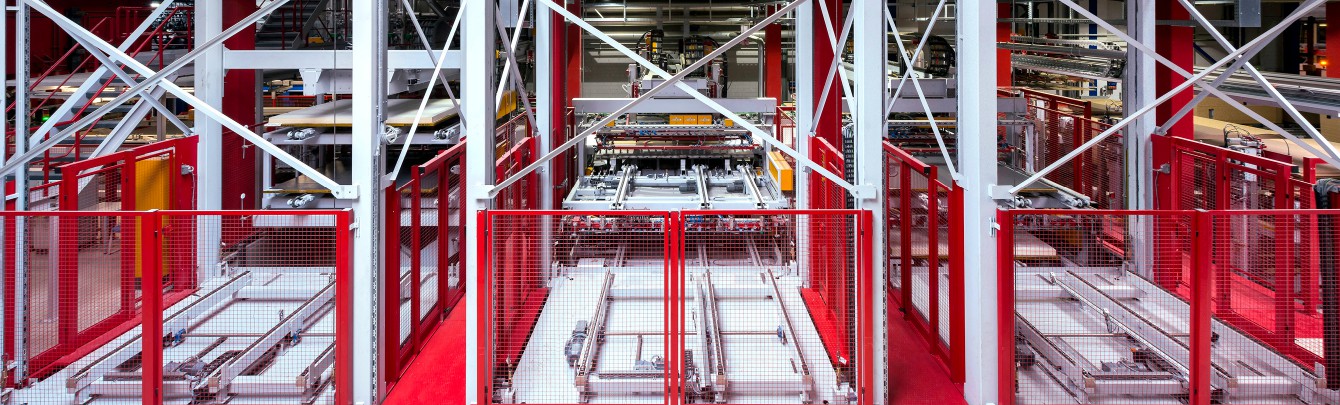

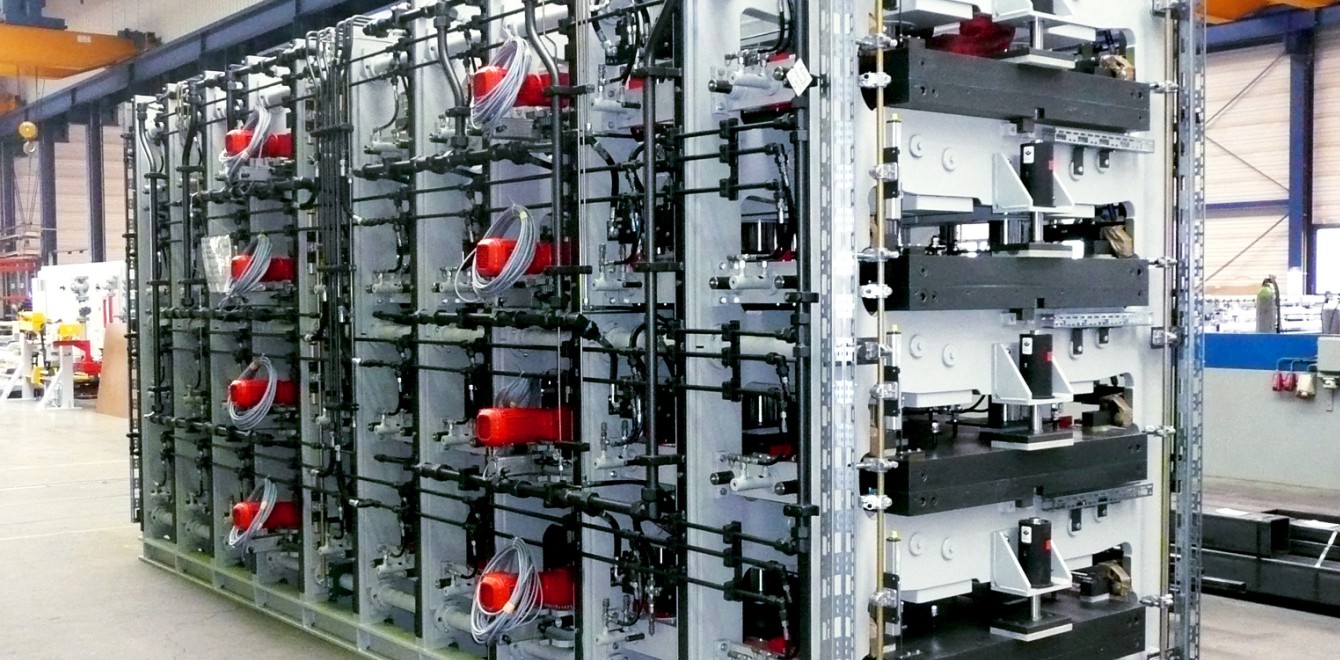

We are also experts in this field: Special press lines for your production.

Wemhöner special press lines can be found in almost all branches of industry: In the production of high-tech composite materials, laminates and fibre composites or for the vulcanisation process. For example, we develop and manufacture not only embossing presses, mould presses and vulcanisation lines, but also cold press lines or systems for the production of three-layer panels. The product portfolio is further complemented by systems for the automotive industry, for the production of photovoltaic modules and laboratory presses.